As the policy of energy conservation and emission reduction continues to be deeply rooted in the hearts of the people, many enterprises intend to use the biogas part of the sewage station to replace natural gas and enter the boiler for combustion or power generation. Then, the hydrogen sulfide removal process (desulfurization) before biogas utilization has become a difficult choice for factories and station owners. At present, the commonly used processes include dry desulfurization, wet desulfurization and biological desulfurization. This paper will give you a simple description and comparison of the three processes.

1、 Common desulfurization processes

1)Dry desulfurization

Biogas flows out from one end of the desulfurization tower after being purified by the packing layer (the main components are activated carbon and iron oxide) and from the other end. Hydrogen sulfide reacts with iron oxide in the filler layer to form iron sulfide; Regeneration can be carried out after the iron oxide reaction is completed.

Desulfurization principle:

Fe2O3 · H2O+ 3H2S = Fe2S3 + 4 H2O

Regeneration principle:

Fe2S3 + 3/2 O2+ 3 H2O = Fe2O3 ·H2O + 2 H2O+ 3 S

2)Wet desulfurization

Wet desulfurization is to send the biogas into the scrubbing tower, wash and absorb it with alkaline solution, and then flow out. The scrubbing solution enters the rich solution tank and regeneration tank. Through catalysis and oxidation with chemical agents, Z finally converts the sulfide into elemental sulfur (sulfur foam), and the absorption solution can be regenerated and recycled.

The process flow diagram is as follows:

3)Biological desulfurization

Biological desulfurization is also a kind of wet desulfurization. Compared with the above catalytic oxidation process of wet desulfurization, the difference is that Thiobacillus is used instead of chemical catalyst to directly oxidize sulfide into sulfur.

Reaction principle:

H2S + OH-= HS- + H2O

HS- + 1/2O2= So + OH-

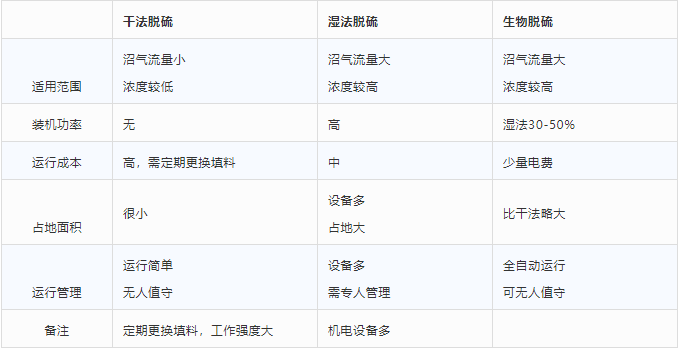

2、 Comparison of common biogas desulfurization processes

explain:

1) Dry desulfurization is mostly used under the condition of low hydrogen sulfide treatment load or high desulfurization effect. At this time, dry desulfurization is mostly used for further desulfurization after wet desulfurization or biological desulfurization.

2) When formulating the desulfurization effect, it is suggested to formulate a reasonable desulfurization effect according to the limitation of subsequent equipment (boiler or generator) on the concentration of hydrogen sulfide and the proportion of biogas and natural gas consumption. We usually recommend that the hydrogen sulfide content of Z terminal be controlled at 25 ~ 100ppm.